Product Name:

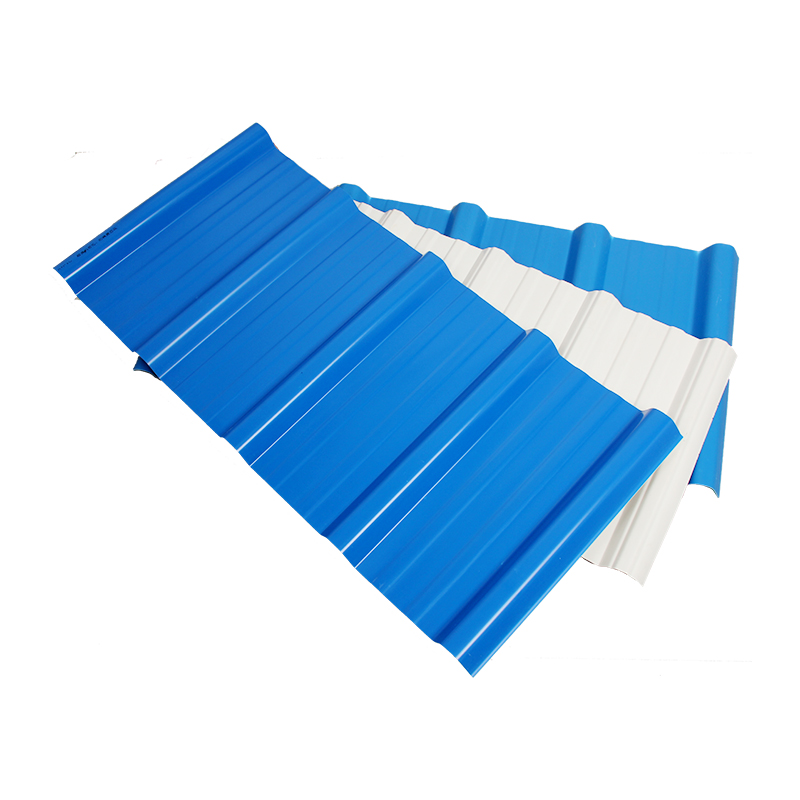

Chinese advanced roofing UPVC materials sheet noise reduction roof tile

Product Overview:

Chinese high-grade UPVC noise-reducing roofing tiles are a new type of roofing material made from unplasticized polyvinyl chloride using advanced co-extrusion technology. They not only provide basic wind and rain protection, but also integrate excellent noise reduction performance, durable weather resistance, and aesthetically pleasing decorative effects, making them an ideal choice for modern buildings, especially noise-sensitive buildings (such as residences, schools, and hospitals).

1. UV Resistance: The co-extruded UV protective layer effectively resists ultraviolet rays from sunlight, preventing material aging and fading, ensuring long-lasting and vibrant colors.

2. Corrosion Resistance: It has strong resistance to harsh weather conditions such as acid rain and salt spray, making it suitable for coastal and industrial areas.

3. Impact Resistance: The material is tough and can withstand impacts from external forces such as hail, and is not easily broken.

4. Fire Retardant: UPVC material itself has self-extinguishing properties, meeting building fire safety requirements.

5. Thermal Insulation: The material has a low thermal conductivity, helping to maintain stable indoor temperatures and saving energy consumption.

6. Recyclable Material, in line with environmental protection principles.

Product Specifications:

| Origin: | Foshan, Guangdong |

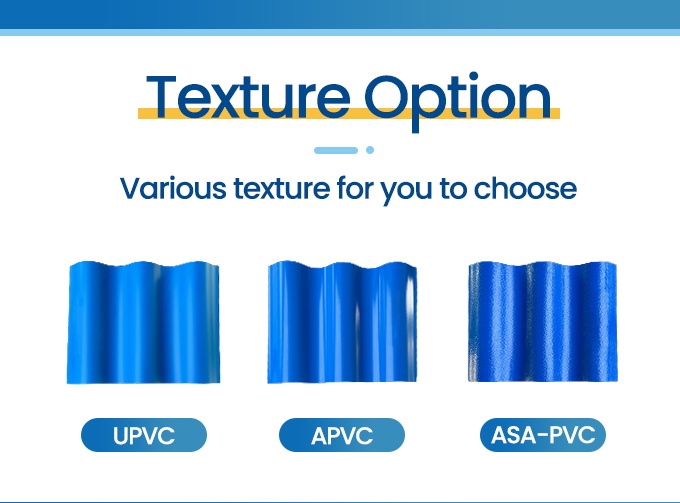

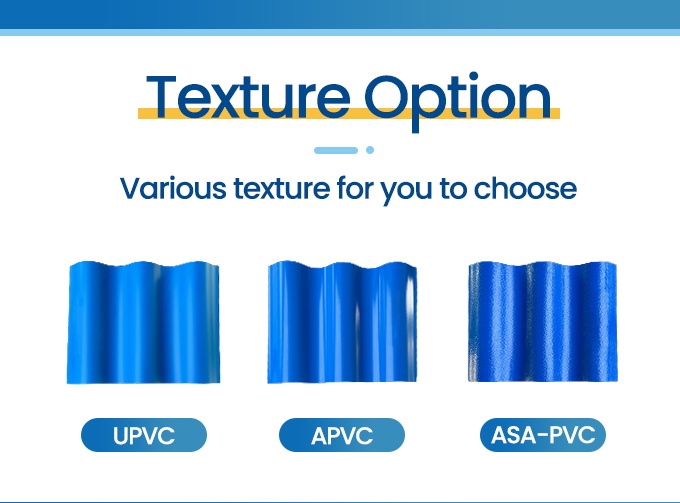

| Material: | APVC/UPVC |

| Length: | Customizable |

| Width: | Customizable |

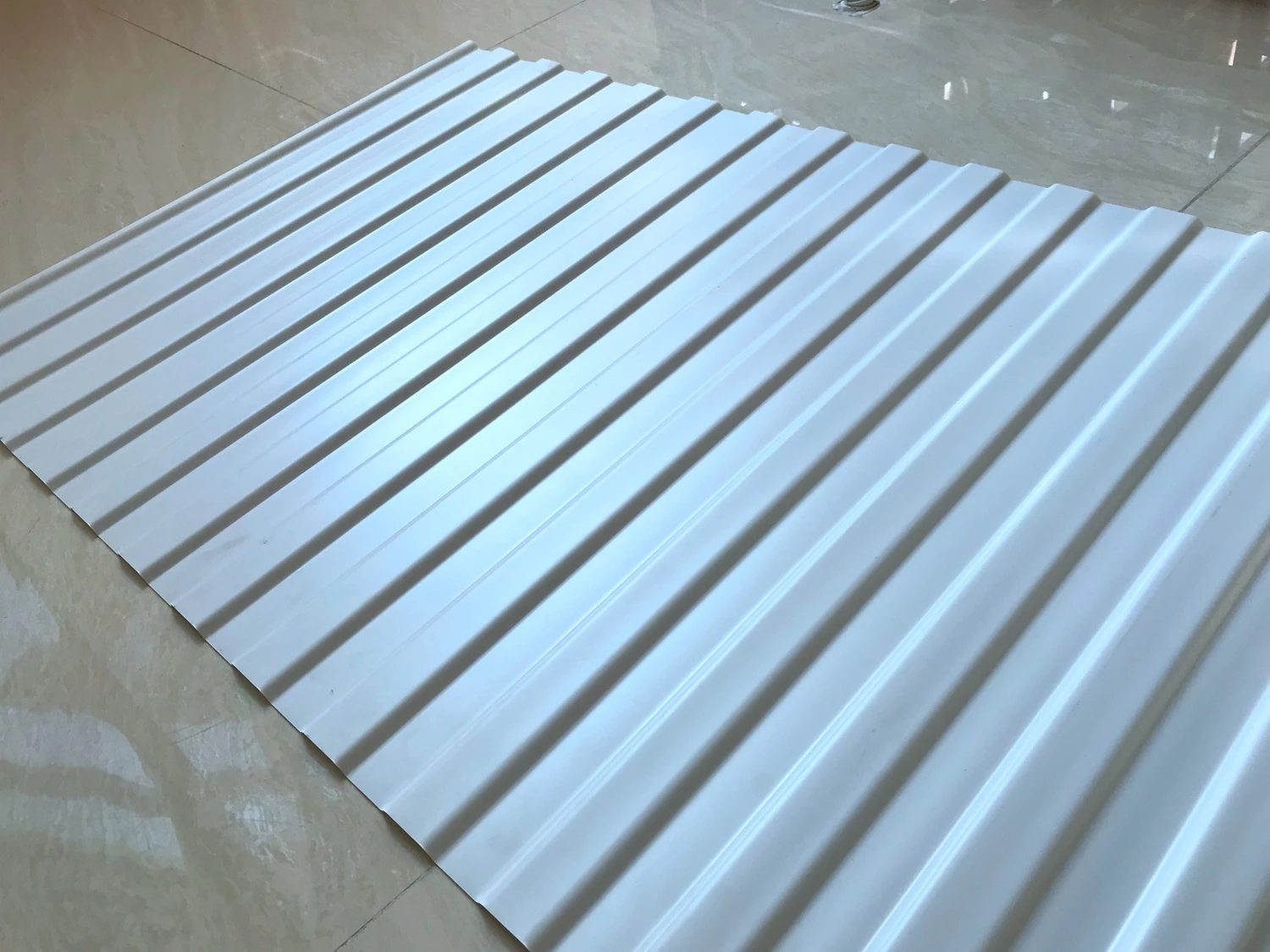

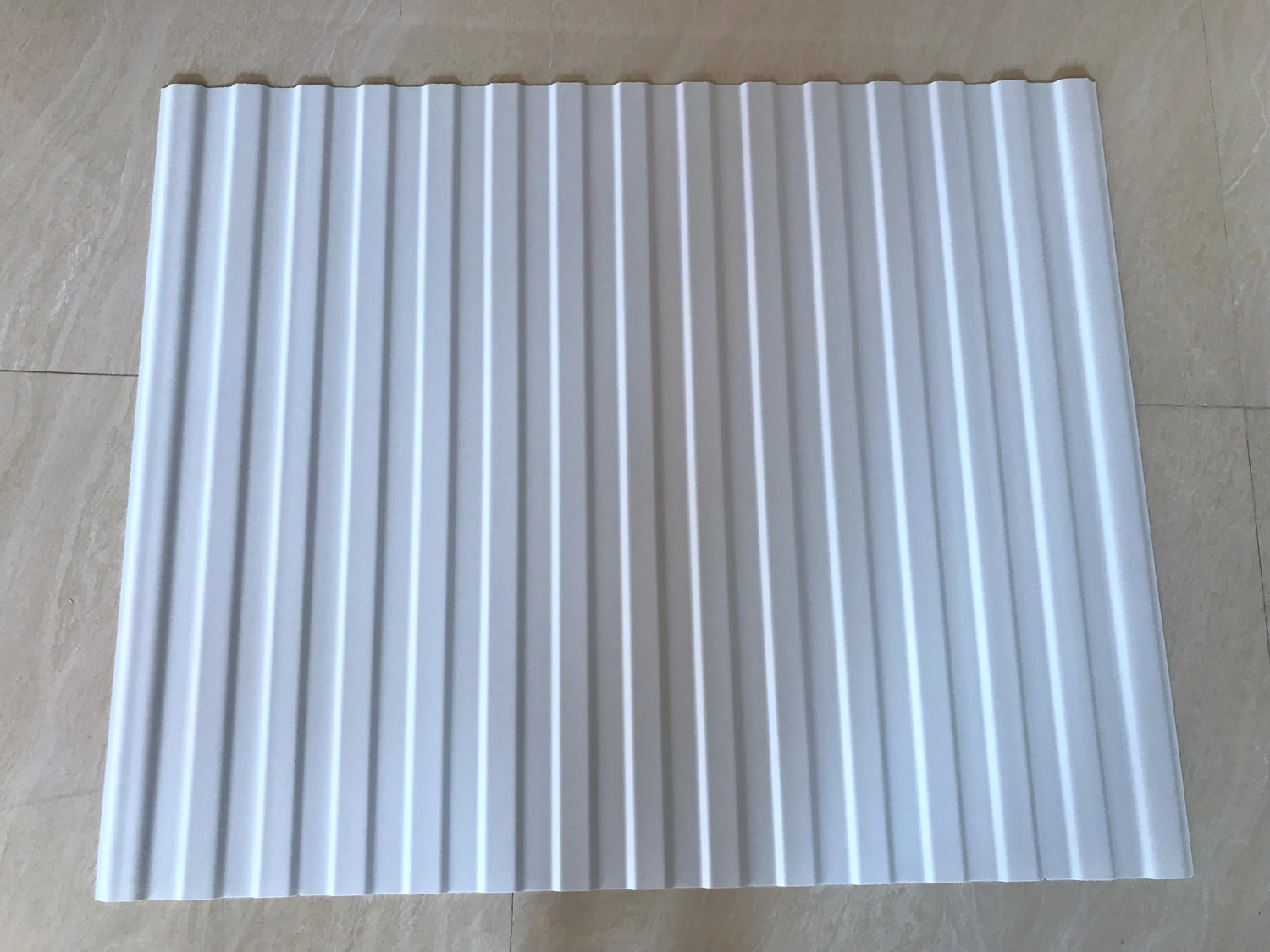

| Thickness: | 1.0mm-3.0mm (Customizable) |

| Color: | Blue and white (Other colors available upon request) |

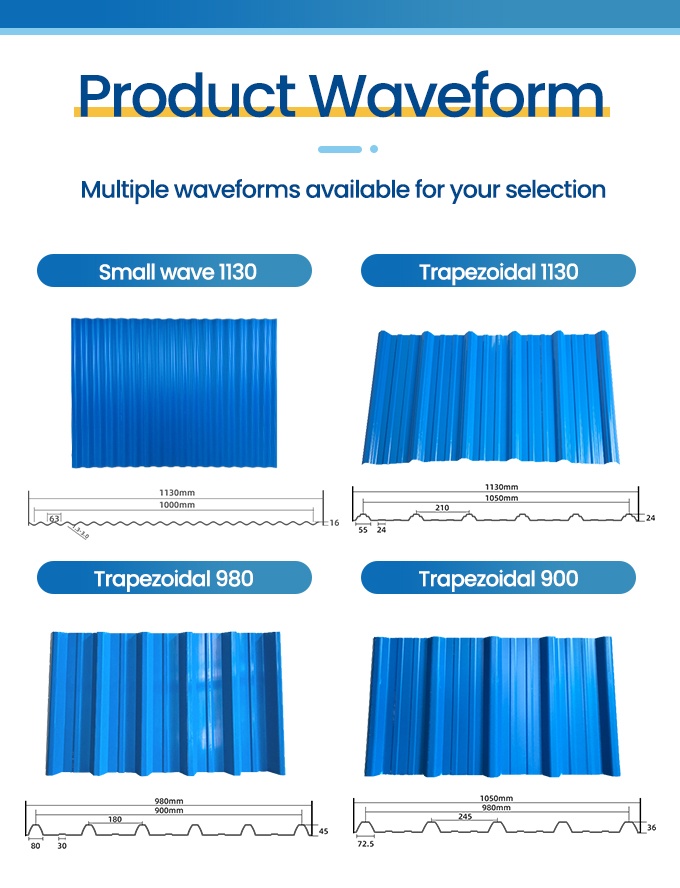

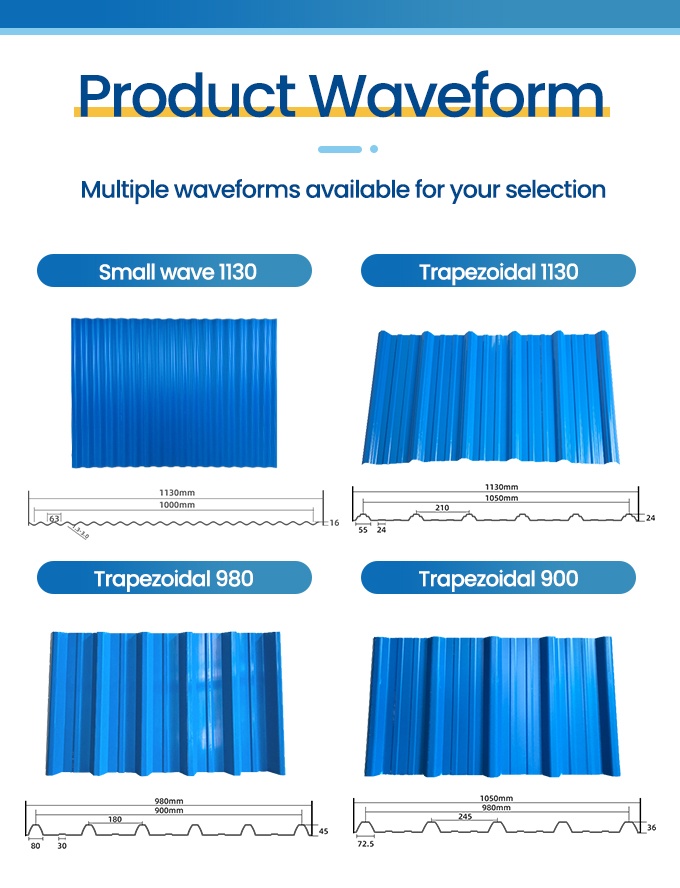

| Wave Pattern: | Large pits, small waves, high waves |

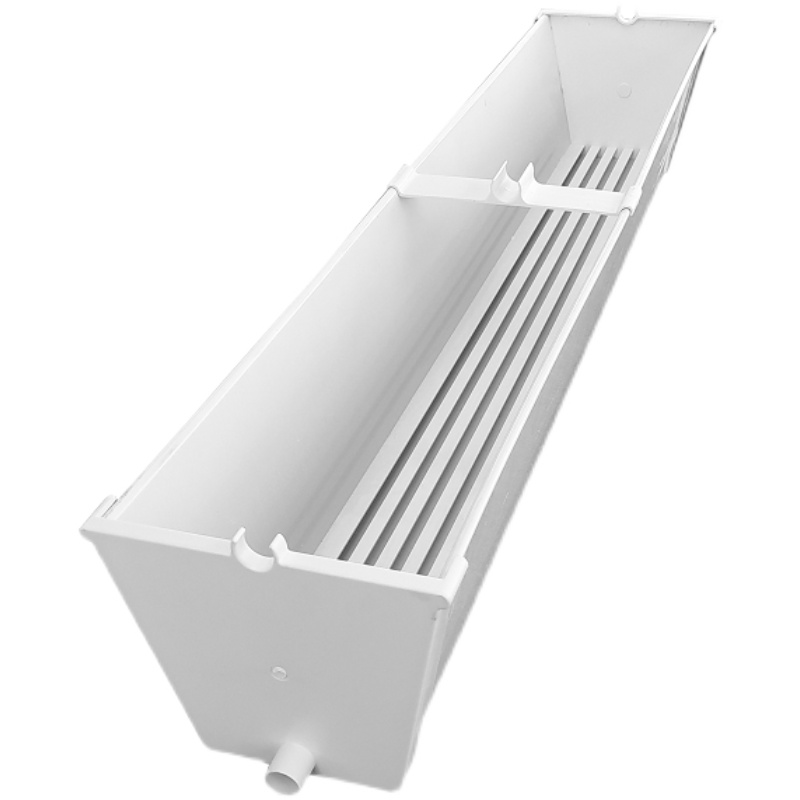

| Applications: | Corrosive environments, factories, pig sheds, warehouses, carports, awnings, roofing materials, factories, chemical plants, farms, ceramic factories, fertilizer plants |

We have blue, white, and green in stock; other colors can be customized, and delivery can be completed within 7 days.

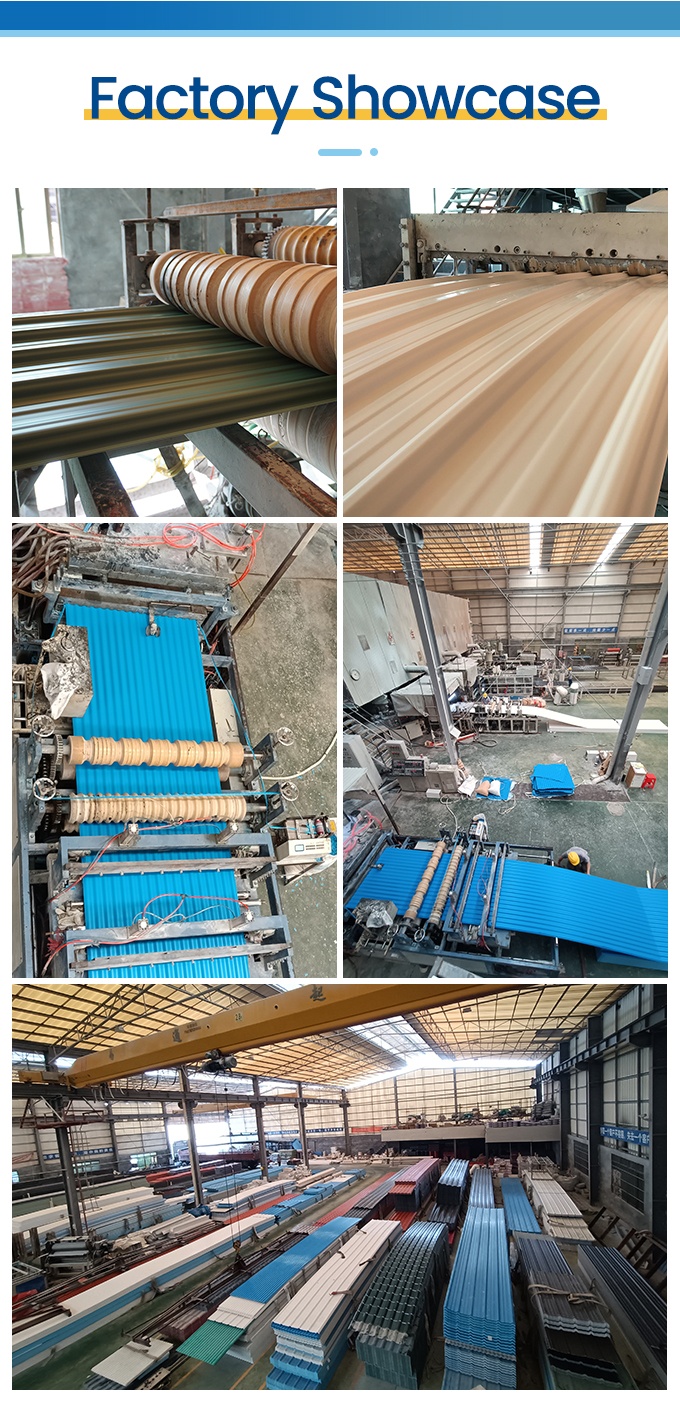

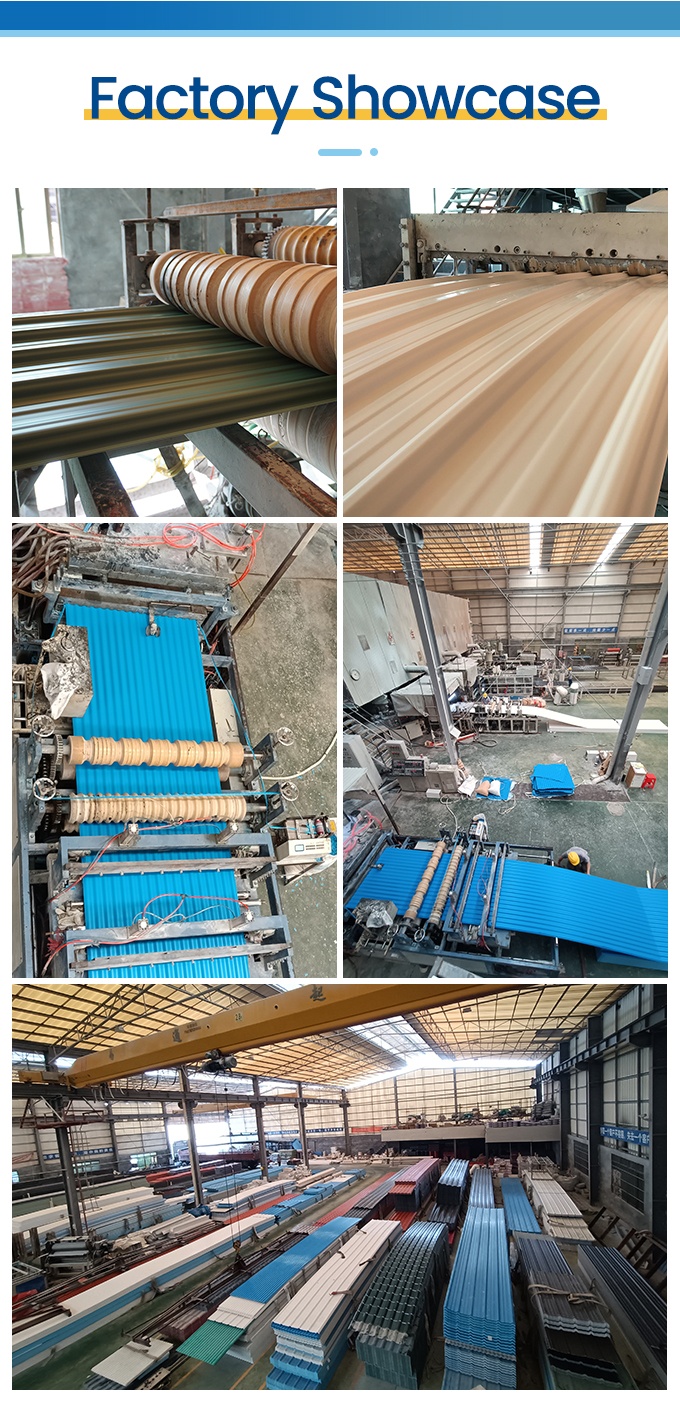

For over 15 years, NANXING Plastic Products Co., Ltd. has been at the forefront of advanced roofing solutions. As a trusted manufacturer with a proven track record, we have successfully sheltered over ten million roofs worldwide. This unparalleled experience is engineered into every sheet we produce, offering an unbeatable combination of durability, energy efficiency, and value.

Applications

Our APVC roofing sheets are the ideal choice for:

Industrial Factories & Warehouses

Manufacturing Plants & Workshops

Agricultural Greenhouses & Livestock Barns

Cold Storage & Food Processing Facilities

Parking Shelters & Canopies

Stadium Skylights & Atriums

Commercial Complexes & Logistics Centers

(FAQ)

Q1: What exactly is UPVC?

A: UPVC stands for unplasticized polyvinyl chloride. It differs from regular PVC in that it doesn't contain plasticizers, resulting in higher hardness, strength, durability, and better resistance to chemical corrosion. It's a mature and reliable synthetic material widely used in the construction industry.

Q2: Is its sound insulation really that good?

A: Yes, very good. UPVC material itself has a high density, effectively absorbing and blocking sound waves. Compared to traditional metal roofing tiles, you can barely hear the crackling noise during rain, creating a very quiet indoor environment, especially suitable for noise-sensitive areas such as residences, hospitals, and schools.

Q3: Is it fireproof?

A: High-quality UPVC roofing tiles typically meet the B1 fire-retardant standard. This means it has self-extinguishing properties, effectively preventing the spread of flames, making it safer than many traditional roofing materials.

Q4: How long do UPVC tiles last? Will they fade?

A: High-quality products can last for more than 20 years. The surface layer is typically co-extruded with an anti-ultraviolet (UV) coating, effectively preventing fading and aging caused by sun exposure and maintaining long-lasting color stability.

Q5: Is it environmentally friendly?

A: Yes. UPVC material itself is recyclable. Many manufacturers use recycled materials in production, aligning with environmental protection principles. Furthermore, its production process consumes less energy than clay or cement tiles.

Q6: Is installation complicated?

A: Not complicated. UPVC tiles are usually designed with convenient overlapping or interlocking systems, making installation very similar to "building blocks." They are lightweight, easy to cut and handle, significantly shortening the construction cycle and reducing labor costs.

Q7: What are the requirements for the roof frame structure?

A: Because UPVC tiles are very lightweight, they place low load requirements on the roof truss and can even be installed directly on existing roofs (where the structure allows), without the need for expensive structural reinforcement.

Q8: Does it require maintenance?

A: Virtually maintenance-free. The smooth surface does not attract dust, and rainwater can keep it clean. It's mold- and moss-resistant, requiring no regular cleaning like other materials.

Q9: Can it withstand harsh weather, such as hail or typhoons?

A: Yes. UPVC shingles have high impact resistance and can withstand the impact of medium-sized hailstones. With professional installation (such as proper fasteners and spacing), it also has good wind uplift resistance.

Q10: How waterproof is it?

A: Excellent. UPVC itself is 100% waterproof. Combined with the tight overlap between the shingles, it forms a seamless waterproof layer, fundamentally solving leakage problems.

Q11: Is it suitable for all climates?

A: Very versatile.

Hot regions: UV resistant, high-temperature resistant, and not easily deformed.

Damp/coastal regions: Corrosion resistant, rust-free, and mold-resistant.

Cold regions: Good low-temperature resistance and will not crack due to freeze-thaw cycles.

Q12: What types of roofs can it be used on? A: It has a very wide range of applications, including:

Residential villas, bungalows

Commercial buildings: shopping malls, factories, warehouses

Public facilities: schools, stadiums, farmers' markets

Pitched roofs are the best application scenario, usually requiring a slope of more than 15 degrees to ensure drainage.

English

English

Español

Español  Français

Français  Deutsch

Deutsch  Русский

Русский  Português

Português  العربية

العربية  日本語

日本語  한국어

한국어  Italiano

Italiano  Nederlands

Nederlands  Türkçe

Türkçe  Polski

Polski  Tiếng Việt

Tiếng Việt  ไทย

ไทย  Bahasa Indonesia

Bahasa Indonesia  Bahasa Melayu

Bahasa Melayu